Forklift Seat Belt Safety: Why It Matters and How to Enforce It

Forklifts are essential tools in many industries, enabling efficient material handling and operations. However, their operation comes with inherent risks, making safety protocols paramount. One of the most critical safety measures for forklift operators is the consistent use of seat belts. This article explores the importance of forklift seat belt safety, the dangers of neglecting them, and best practices to ensure operator protection.

The Evolution of Seat Belt Awareness

If you are old enough to remember riding in a car during the 1960s through the mid-1980s, you’ll probably recall not always being diligent about wearing a seat belt. It wasn’t until 1985 that the NHTSA and the Ad Council launched advertising campaigns with Vince and Larry, the crash test dummies, to highlight the life-saving benefits of seat belts. The commercials graphically demonstrated the severe consequences of not buckling up.

In 1993, the ‘Click It or Ticket’ program was introduced in North Carolina. This initiative gradually spread across the country, and by 2004, all states and territories participated. Today, seat belts are recognized as one of the most effective safety features, saving tens of thousands of lives each year.

If seat belts are universally acknowledged as essential in passenger vehicles, why do so many forklift operators still neglect to use them?

Even one story like this is one too many:

On July 2, 2001, a 17-year-old male warehouse laborer (the victim) was fatally injured when the sit-down type forklift he was operating tipped over and crushed him. The victim apparently lost control of the forklift, which had a load on its forks and the mast fully extended, as he was making a right turn, causing the forklift to tip over 90 degrees onto its left side.

The unrestrained victim was crushed under the extended boom/mast of the forklift. Fire department personnel responded seven minutes after receiving a 911 call from company personnel and, together with police officers, pulled the victim clear as company employees used two forklifts to lift the forklift from the victim.

The victim was unconscious and bleeding from head injuries. First aid was provided by emergency medical services (EMS) personnel, and the victim was transported to an area hospital, where he was pronounced dead at 1:35 p.m., approximately 25 minutes after the incident.

Why Forklift Seat Belts Are Critical

The Risk of Tip-Overs

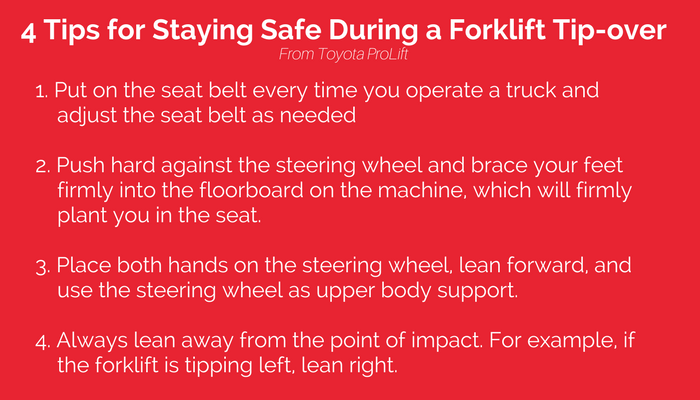

Tip-overs are the leading cause of fatal forklift accidents. Forklifts have a high center of gravity, making them prone to tipping if an operator turns too quickly, drives on uneven surfaces, or carries an imbalanced load. When a tip-over occurs, the instinct to jump can be deadly, as operators often cannot escape the machine in time.

A seat belt keeps the operator securely inside the protective confines of the forklift. Instead of being ejected and crushed, the operator remains in the seat, significantly reducing the risk of serious injury or death.

The Reality of Forklift Accidents

Every year, forklift-related accidents result in severe injuries and fatalities. Many of these incidents involve operators who were not wearing seat belts. Tragic stories like the one above illustrate just how quickly an avoidable accident can turn fatal when seat belt safety is ignored.

Common Reasons Forklift Operators Skip Seat Belts

Even with clear risks, some forklift operators still neglect to wear seat belts. Here’s why:

- False Sense of Security – Some operators believe that forklifts are too sturdy to tip over or assume they can react quickly enough to avoid injury.

- Complacency – Those working in the same environment every day may think accidents won’t happen to them.

- Discomfort or Inconvenience – Some operators avoid seat belts because they find them restrictive or believe fastening them slows down their work.

However, no amount of confidence or experience can prevent an accident. Seat belts should always be worn—no exceptions.

Forklift Seat Belt Requirements and OSHA Regulations

While specific seat belt regulations for forklifts may not always be detailed, safety agencies require employers to eliminate recognized hazards in the workplace. Failing to enforce seat belt use can result in citations, fines, and most importantly, increased risk to workers. Businesses are responsible for ensuring that forklift operators comply with safety standards, including mandatory seat belt usage.

Best Practices for Enforcing Forklift Seat Belt Safety

1. Prioritize Training

Ensure all forklift operators understand the risks of not wearing a seat belt and how it can save their lives. Regular safety training should emphasize the importance of securing the seat belt every time they operate the vehicle.

2. Conduct Regular Safety Inspections

Supervisors should routinely check that seat belts are in good condition and that operators use them consistently. Regular forklift safety audits can help reinforce compliance.

3. Foster a Safety-First Culture

Encourage a workplace culture where safety is non-negotiable. Recognize and reward operators who follow safety protocols and make it clear that seat belt use is mandatory.

4. Address Operator Concerns

If operators find seat belts uncomfortable or impractical, investigate alternative designs that improve comfort while maintaining safety. Removing obstacles to compliance can increase seat belt usage rates.

The Bottom Line: Buckle Up Every Time

Forklift seat belts are not optional accessories—they are life-saving devices. Operators and employers alike must recognize their importance and ensure compliance. By making seat belt use a consistent habit, workplaces can significantly reduce injuries and fatalities, ensuring that every operator gets home safely at the end of the day.

A few seconds is all it takes. Buckle up. It’s worth it.