Here at The Forklift Pro, our maintenance checks on new and used equipment don’t stop with the moving parts. Every piece of equipment is thoroughly checked before reaching your facility. What’s under the hood is just as important, and we take extra care to ensure that the battery in your forklift is operating at a peak level of performance.

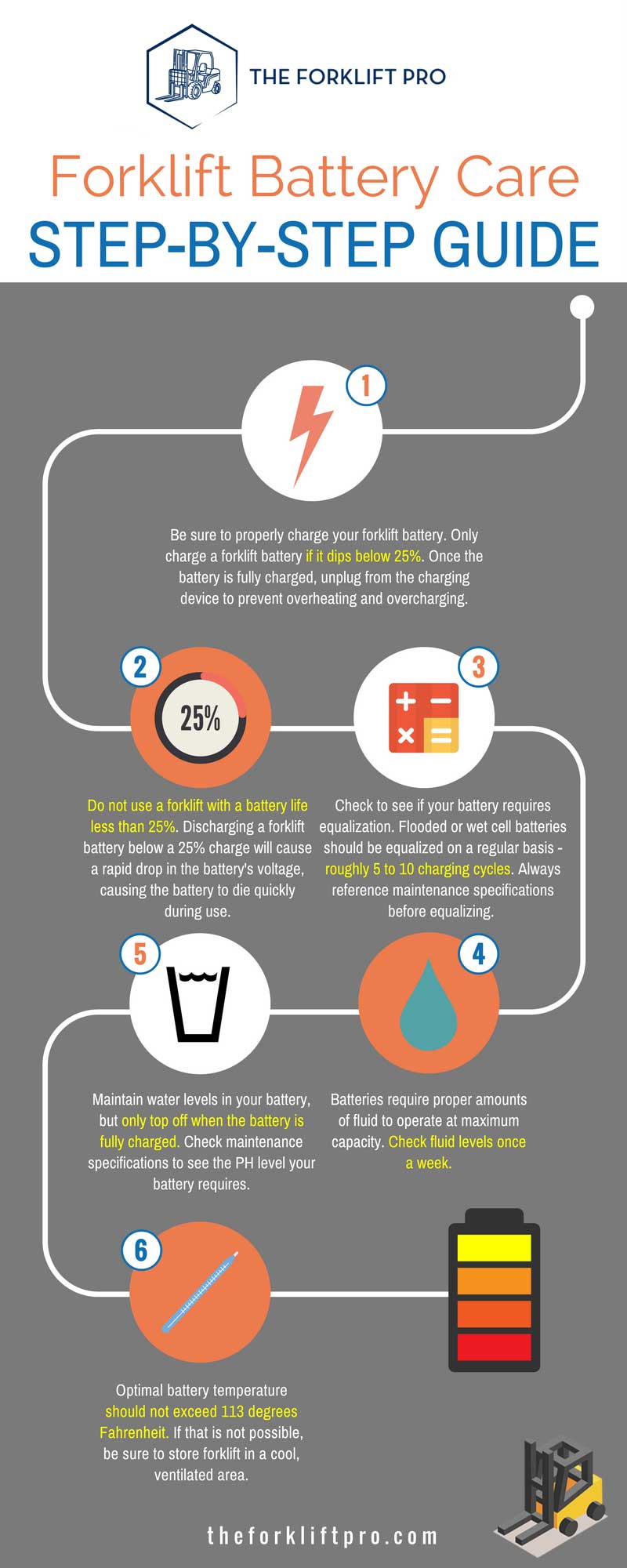

Forklift Battery Care: Step-by-Step Guide

1. Be sure to properly charge your forklift battery. Only charge a forklift battery if it dips below 25%. Once the battery is fully charges, unplug the charging device to prevent overheating and overcharging.

2. Do not use a forklift with a battery life less than 25%. Discharging a forklift battery below a 25% charge will cause a rapid drop in the battery’s voltage, causing the battery to die quickly during use.

3. Check to see if your battery requires equalization. Flooded or wet cell batteries should be equalized on a regular basis – roughly 5 to 10 charging cycles. Always reference maintenance specification before equalizing.

4. Batteries require proper amounts of fluid to operate at maximum capacity. Check fluid levels once a week.

5. Maintain water levels in your battery but only top off when the battery is fully charges. Check maintenance specifications to see the PH level your battery requires.

6. Optimal battery temperature should not exceed 113 degrees Fahrenheit. If that isn’t possible, be sure to store forklift in a cool ventilated area.

Of course, the battery of a forklift is just one step in the process. You can find out more about our material handling equipment check-in process here, learn more about the benefits of buying used equipment, or check out some of our current inventory.

Our team is ready to assist you each step of the way throughout the forklift buying or selling process and will talk with you about the condition of the equipment.