When summer temperatures rise, so do the risks to your forklifts and operators. Excessive heat can lead to engine overheating, battery failure, and even unsafe working conditions for your team. That’s why seasonal forklift maintenance is critical to preventing costly repairs, reducing downtime, and protecting your investment. Maintaining your forklifts should always be a priority in order to keep them running efficiently and safely – especially in extreme temperatures. Excessive heat exposure can lead to increased forklift engine wear and failure of parts, which in turn creates expensive replacements. We have a few preventative measures for summer forklift care to add to your morning safety checklist.

1. Inspect the Battery for Heat-Related Issues

While checking your forklift battery is typically part of everyday maintenance, hot weather accelerates fluid evaporation in batteries, which can lead to corrosion, reduced battery life, and equipment failure. While battery checks should already be part of your daily forklift inspection, summer requires extra attention.

-

Check fluid levels regularly and top off with water that matches your battery’s pH requirements

-

Clean corrosion from terminals and ensure secure cable connections

-

Consider scheduling mid-season battery service to extend battery life

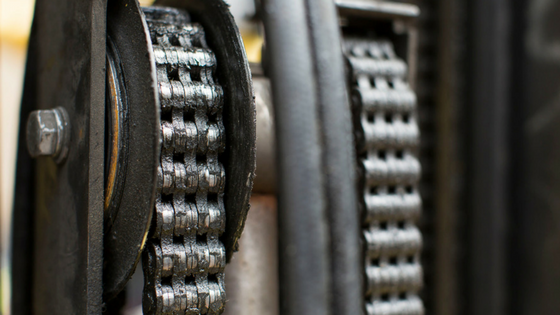

2. Examine Forklift Cables, Chains, and Connectors

Rapid temperature changes can cause cables to become brittle and connectors to loosen. During the summer, previously unnoticed damage from colder seasons may worsen.

-

Look for cracks, fraying, or exposed wiring in cables

-

Ensure all connectors are secure and functioning properly

-

Inspect lift chains for wear, elongation, or signs of rust

3. Check Engine Oil and Replace When Necessary

Your forklift’s engine oil plays a major role in keeping parts lubricated and preventing overheating. Old or insufficient oil can cause increased friction, which leads to engine strain or complete failure.

-

Follow the manufacturer’s recommended oil change intervals

-

Use the correct oil type for your specific forklift model

-

Check oil levels frequently during extreme heat

4. Maintain Your Cooling System

The radiator is the forklift’s first line of defense against overheating. Make radiator inspections part of your routine during the summer months.

-

Ensure coolant levels are within the proper range

-

Inspect the radiator and hoses for cracks, leaks, or loose fittings

-

Use the right type of coolant designed for your forklift model

-

Clear away any debris from the radiator screen to improve airflow

5. Inspect Belts and Fans for Wear

Your forklift’s fans and belts work together to cool the engine and circulate air. Damage to either can lead to inefficient cooling and engine trouble.

When inspecting fans and belts, look for:

-

Cracks or holes

-

Signs of excessive wear or slippage

-

Fraying or loose components

-

Proper tension and alignment

Routine inspections will help you identify potential failures before they become expensive problems.

6. Protect Your Operators from Heat Stress

Summer forklift care goes beyond the machine. Your operators are vulnerable to heat-related illness, especially in unventilated or poorly cooled warehouses.

-

Provide shaded or air-conditioned break areas

-

Encourage frequent water breaks and monitor hydration

-

Install industrial fans in high-traffic work zones

-

Schedule intensive tasks during cooler parts of the day, such as early mornings

-

Train staff to recognize symptoms of heat exhaustion or heat stroke

Happy and healthy operators are more productive and less likely to make mistakes due to fatigue or overheating.

7. Additional Tips for Summer Warehouse Safety

In addition to forklift-specific maintenance, keep your facility summer-ready:

-

Use reflective window film or shades to reduce indoor heat buildup

-

Check ventilation systems to ensure proper airflow

-

Store forklift accessories and batteries in climate-controlled areas

Keeping the entire warehouse environment cool and safe benefits both your equipment and your team.

Summer Forklift Care at The Forklift Pro

Your forklifts and your warehouse need these proper cooling procedures in place in order to avoid unnecessary and costly heat-related equipment (and driver) malfunctions. In the scorching heat of summer, maintaining your forklifts should always be a top priority to keep them running efficiently and safely. Extreme temperatures can wreak havoc on your forklifts, leading to increased engine wear and the failure of critical parts. These issues can quickly result in expensive replacements and downtime.

Good news – we give all of our inventory a thorough inspection during intake, as well as routine maintenance and a safety check before selling! If you’re ready to buy or sell material handling equipment, we’re ready to help.