Your forklifts and your warehouse need proper cooling procedures in place in order to avoid unnecessary and costly heat-related equipment (and driver) malfunctions, and we’ve put together this checklist for forklift care in the summer.

Maintaining your forklifts should always be a priority in order to keep them running efficiently and safely – especially in extreme temperatures. Excessive heat exposure can lead to increased forklift engine wear and failure of parts, which in turn creates expensive replacements. We have a few seasonal preventative measures to add to your morning safety checklist.

First Thing First – Check the Battery

While checking your forklift battery is typically part of everyday maintenance, the summer heat presents unique concerns, particularly regarding excess corrosion and low fluid levels. The extreme heat can cause rapid evaporation of battery fluids, significantly shortening the life of your forklift’s battery. Ensure that your battery’s water levels are correct, and if you find that fluid levels are low, make sure you’re refilling with water that has the right pH for your specific battery model.

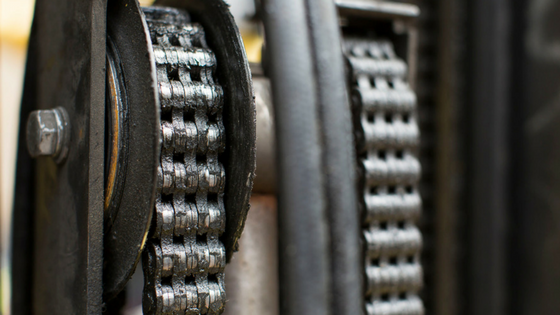

Inspect Cables, Chains and Connectors

As temperatures rise, the previous colder weather can have a lingering impact. Colder weather can cause cables to become brittle. The extreme shift in temperature can damage the wires and cables, so make sure you thoroughly inspect them to ensure they are intact. See to it that wiring isn’t exposed and that cable connections are firing. Additionally, inspect your forklift chains for any signs of wear or weakness.

Protect Your Engine – Check the Oil

Having the correct oil for your forklift is essential to its functionality. Just like any other engine-powered machine, you want to be sure the oil is changed when recommended. A lack of engine oil (or old engine oil) can cause your engine to wear down and could also possibly lead to total engine failure.

Remember the Lifeline – The Engine

Overheating is a major concern during the summer months, and a radiator in good working order will be your forklift’s best defense. If your coolant is running low, check for any cracks in the radiator before adding fluid. Also, conduct a thorough inspection of your hoses for holes, cracks, or loose connections before refilling the tank. Ensure that you’re using the right coolant specifically designed for your forklift model. This is also an ideal time to clear any debris from the radiator screen.

Fans & Belts – More Cool Essentials

Properly functioning fans and belts are vital to preventing your forklift from overheating in the summer heat. Engine fans help dissipate heat from your engine’s surface, while belts keep the coolant moving and provide additional airflow over the engine. Here’s what to look for when inspecting your belts and fans:

- Cracks

- Excessive wear

- Holes

- Fraying in the belt system

Ensure your workers are cool, too!

Are your forklift operators taking precautionary measures to stay cool and hydrated? It’s just as important for drivers and workers to stay safe in extreme temperatures. Heat fatigue is a common issue for forklift truck operators. Consider placing fans in the parts of your warehouse where workers are the most. Make sure your operators are able to take breaks in a cooler environment throughout the day. If possible, schedule heavy workloads in earlier parts of the day before your warehouse has had a chance to heat up.

Forklift Care at The Forklift Pro

Your forklifts and your warehouse need these proper cooling procedures in place in order to avoid unnecessary and costly heat-related equipment (and driver) malfunctions. In the scorching heat of summer, maintaining your forklifts should always be a top priority to keep them running efficiently and safely. Extreme temperatures can wreak havoc on your forklifts, leading to increased engine wear and the failure of critical parts. These issues can quickly result in expensive replacements and downtime.

Good news – we give all of our inventory a thorough inspection during intake, as well as routine maintenance and a safety check before selling! If you’re ready to buy or sell material handling equipment, we’re ready to help.